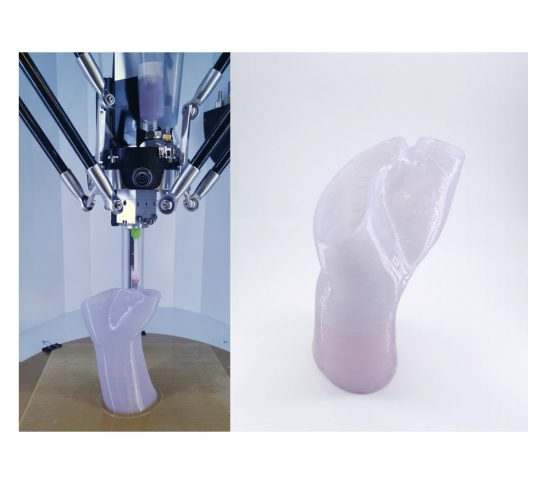

3D Printing, Elastomers, Silicone

COPSIL 3D 4050

REFORMULATED SILICONES RTV-2 high hardness skin contact 3D printing silicone for additive manufacturing. read more

Description

REFORMULATED SILICONES

The latest version of COPSIL 3D silicone offers an extended working time of 50 minutes.

3D printing silicones, COPSIL 3D®, offer a new solution for the design of flexible and complex for small series parts, ideal for prototyping. Silicone elastomers have the same mechanical performance as parts produced by casting or injection molding. This technology produces flexible components while at the same time providing high quality and precision, meeting the most demanding manufacturing requirements.

COPSIL 3D® 4050 silicone elastomer is a two-component silicone, combining resin and hardener in equal parts. This formulation cross-links at room temperature via a polyaddition reaction with a platinum catalyst.

Its unique texture and reactivity greatly simplify the design of parts via 3D printing, offering ease of use.

It has a hardness of 40 Shore A and a mix life of 50 minutes at 20°C.

Packaging :

- 2*50 ml mono-component cartridges

- 2*850 ml mono-component cartridges

- other syringe size and bulk available upon request

Additional information

- Materials

- Chemistry

- Processes

- Hardness

- Mix viscosity at 20°C

- Ratio

- Silicone Type

- Conditionnements

Data sheet