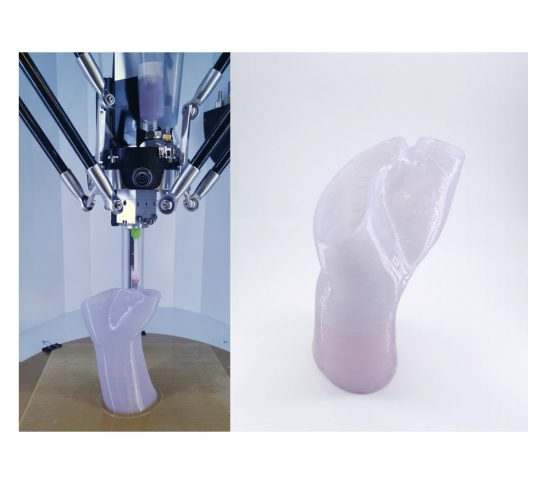

3D Printing, Elastomers, Silicone

COPSIL 3D 1050

REFORMULATED SILICONES Soft RTV-2 silicone for additive manucfacturing. Hardness of 10 Shore A read more

Description

REFORMULATED SILICONES

The latest version of COPSIL 3D silicone offers an extended working time of 50 minutes.

The COPSIL 3D range is designed for the manufacture of flexible parts with complex design or small series production (prototyping). Printed silicone elastomers have mechanical characteristics at least equivalent to parts made by casting or injection.

The silicone elastomer COPSIL 3D 1050 consists of a two-component system (resin and hardener) cross-linking when mixed in 1 : 5 parts at room temperature by a polyaddition reaction with a platinum catalyst. Its unique consistency and reactivity simplify the design of parts through 3D printing. It has a hardness of 10 Shore A and a lifetime at the mixing head of 50 minutes at 20°C.

Product suitable for skin contact applications according to ISO 10993-5

Process: additive manufacturing with two-component printing head

Packaging :

- KIT 6 x 50 ml

- KIT 6 x 850 ml

Additional information

- Materials

- Chemistry

- Processes

- Hardness

- Mix viscosity at 20°C

- Ratio

- Silicone Type

- Conditionnements

Data sheet