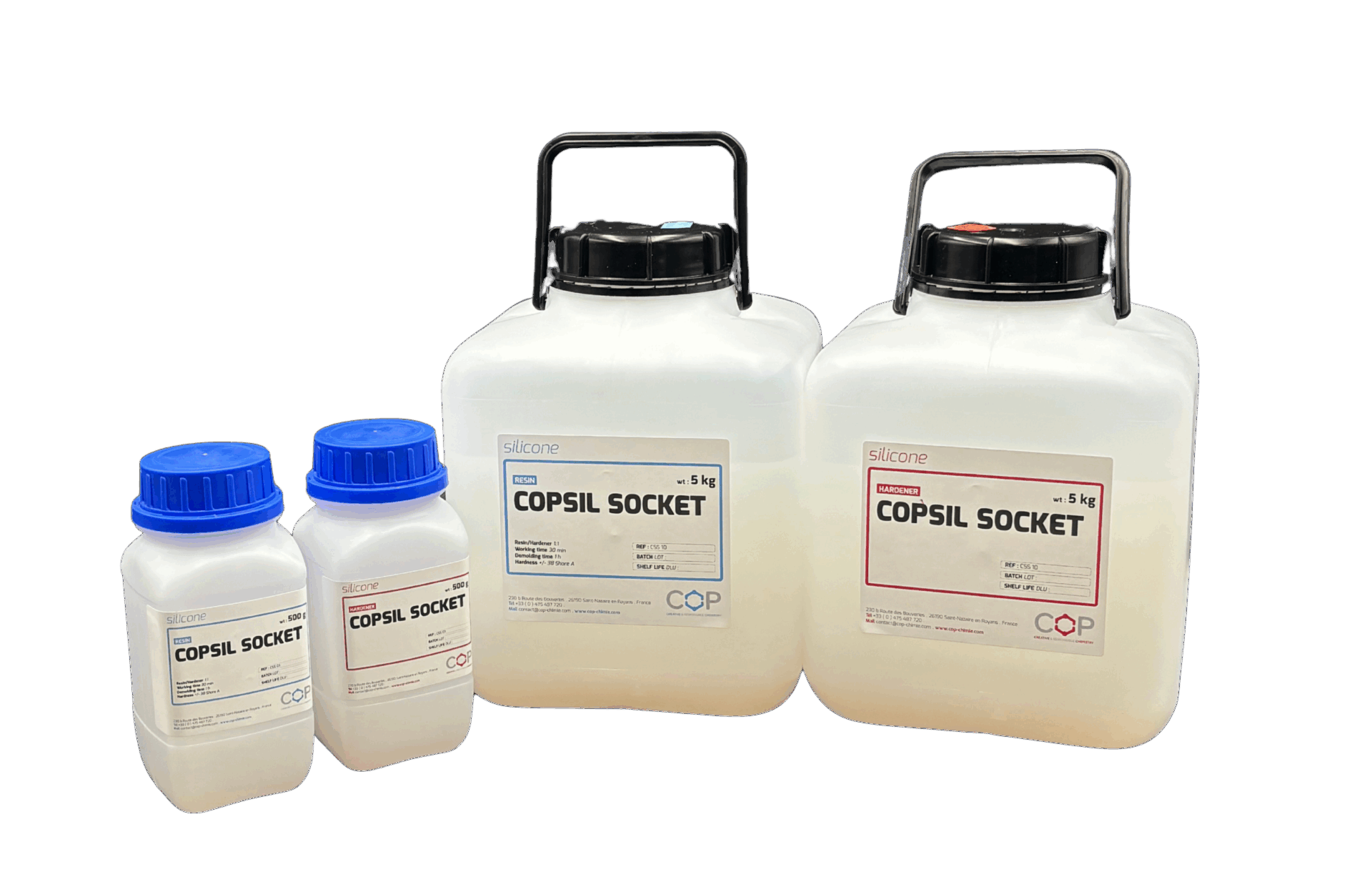

COPSIL SOCKET

Polyaddition silicone for soft socket (in orthopedics), fluid, translucent, two-component and easy to demold. read more

Description

COPSIL SOCKET silicone elastomer is a two-component system (resin and hardener) which is mixed in equal parts and cross-links at room temperature by a polyaddition reaction with a catalyst based on platinum complex, and whose polymerisation can be accelerated by heat. COPSIL SOCKET is used to produce soft sockets (in orthopedics), molds that reproduce details perfectly, and resistant parts. It can also be used for prototyping. Silicone resin is an alternative to acrylic, or polyurethane, or epooxy, or HTV silicones usually used to make soft sockets. It provides greater comfort and flexibility for your devices.

Sold in liquid ready to mix with a 1/1 ratio.

✨ The benefits of COPSIL SOCKET

- Skin contact (ISO 10993-5 standard),

- safe to use in the workshop (components without hazard pictograms or exothermic peak),

- easy to use (no need to warm up the components, no pre-treatment of PVA bags, no need for release agent),

- easier to implement than HTV silicones,

- tested and validated for a reproducible, reliable process,

- can be post-treated with SILISKIN to obtain a soft-touch and anti-dust effect,

- can be custom-colored with our range of RTV colorants,

- stable over time and in response to patient needs.

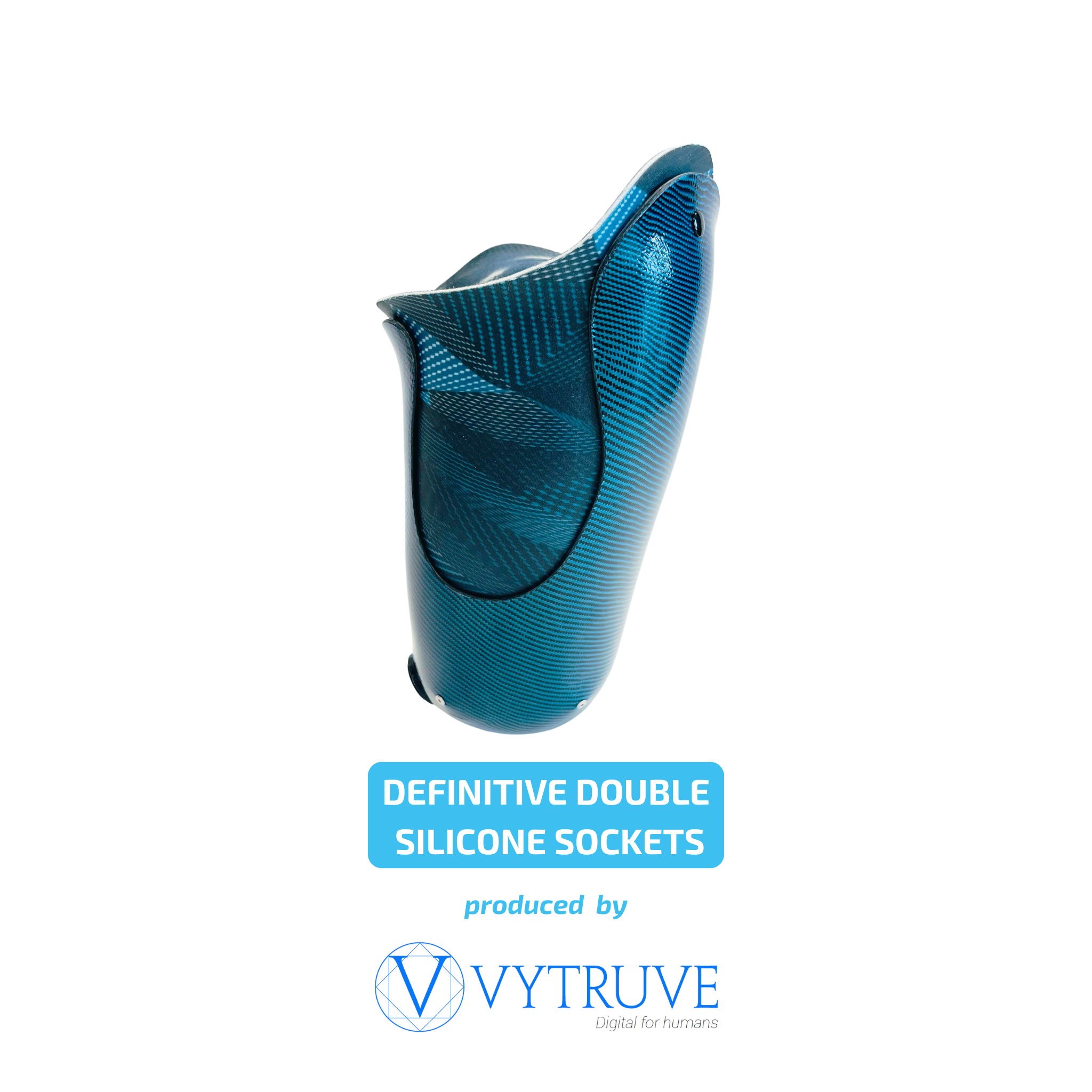

This silicone is used by our partner Vytruve for manufacturing double silicone sockets. Take advantage of their expertise and order your custom sockets directly on their website: vytruve.com/order-sockets.

Additional information

- Materials

- Silicone Type

- Processes

- Application

- Ratio

- Working time at 20°C

- Demoulding time at 20°C

- Mix viscosity at 20°C

- Hardness

Data sheet