Description

ORTHOFLAX® reinforcements have been especially designed and patented to be used with our ORTHOPOXY® resins in Orthopedic field for the manufacturing of prosthetic sockets. Flax fiber provides to the composite some properties never reached by the conventional fibers.

- Health : Flax is not dangerous for human: any particles during the handling of reinforcements, not-irritating and non-allergenic.

- Lightweight : Flax fiber is lighter than carbon and glass fibers.

- Comfort : Flax composites provide damping properties never reached by the other fibers. Hence, orthopedic devices realized with ORTHOFLAX® fibers combined with our ORTHOPOXY® resin improve the comfort for the patient thanks to the reduction of shocks and vibrations during their activities.

Furthermore, flax provides a heat insulation property which is not the case of carbon fiber which is very conductive. Hence, when the weather is very hot, the use of orthopedic devices is easier. - Low environmental impact : Five times less energy necessary to be transformed compared to glass and 20 times less compared to carbon.

- Renewable agriculture resource : 100% of our fibers are produced in France and Belgium, renewable and biodegradable.

- Non abrasive for tools: Compared to carbon or glass fibers, flax doesn’t deteriorate knife edge.

- Compatibility with our acrylic resins COPACRYL : Trials realized by our CPO partners and ourselves have allowed us to confirm this compatibility.

- Impregnability of flax : Compared to synthetic fibers (carbon, glass), the flax structure (cellulose) allows the resin to impregnate the fiber core.

- Architecture : +/- 45°

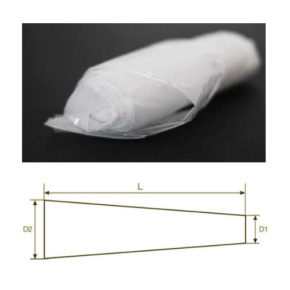

- Diameter : 130 and 150 mm

- Weighing : 133, 203 g/m

- Packaging : 5 mL roll

Additional information

- Accessories

- Type of fiber

- Reinforcement composition

- Length

- Grammage/Diamètre

- Application

Data sheet